Message

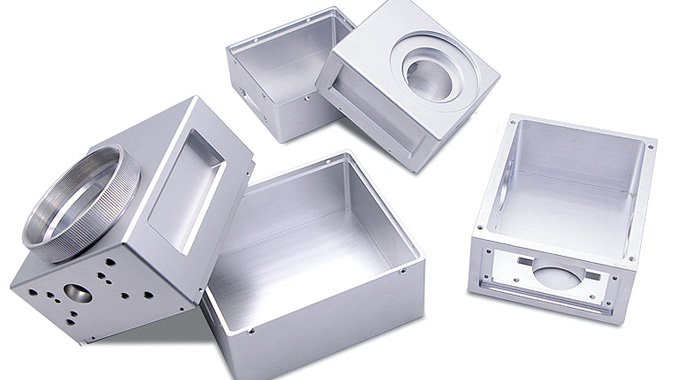

The galvanometer of the laser machine parts is processed with square solid material. CNC processing takes 35 minutes, which wastes materials and the processing cost is beyond the acceptable range of customers. In order to reduce costs, our engineers use cold forging, which reduces the processing time to 12 minutes and reduces the cost by 60%.

Cold forging + CNC machining

Following the above processing method, we achieved the material required by the customer. During the evaluation process, our engineers also considered using die casting for production, but the die casting material is ADC12, which cannot meet the customer's requirements and has lower strength than the customer's AL6061. For this reason, we rejected this idea.

T6 heat treatment

According to the customer's drawing requirements, the thickness of the material is thickened and a film treatment is performed on the surface of the aluminum plate to increase the fluidity of the aluminum in the mold. After the product is T6 heat treated, we make it through CNC processing according to the customer's drawings.

CNC machining laser machine parts galvanometer

According to the structure of the product and customer requirements, we determine the clamping reference position according to the shape and position tolerance of the parts. On the machine tool, we choose 3+2CNC worktables for processing. In this way, we can mill 5 surfaces at a time and use them directly. Two processings can be performed. It saves clamping time and turnaround time, and the efficiency is increased by 10% again.