Message

The main difference between CNC four-axis machining and five-axis machining lies in the number of axes available for movement and control during the machining process. Here's an explanation of each:

1. CNC Four-Axis Machining:

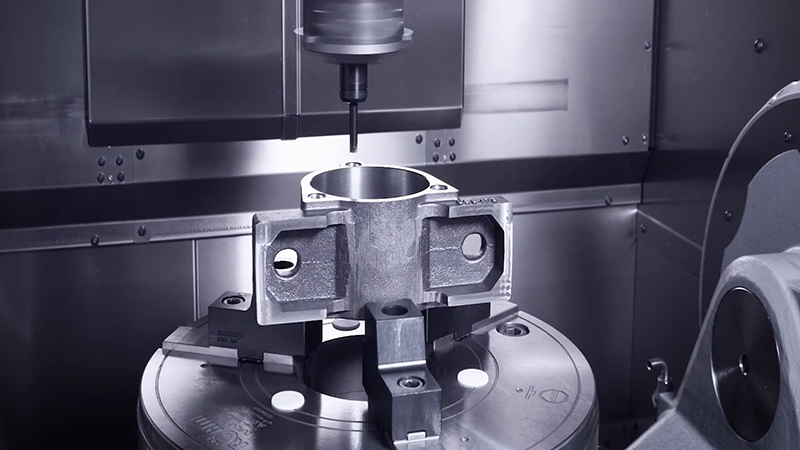

In four-axis machining, the CNC machine operates with four axes of motion: X, Y, Z, and an additional rotary axis (typically referred to as the A-axis). The A-axis enables the workpiece or cutting tool to rotate around a specific axis, usually perpendicular to the X-axis. With four-axis machining, the machine can perform operations on various sides and angles of the workpiece by rotating it around the A-axis. However, the tool is limited to positioning itself along the X, Y, and Z axes.

2. CNC Five-Axis Machining:

Five-axis machining takes the capabilities of four-axis machining further by introducing an additional rotary axis (usually called the B-axis). In addition to the X, Y, Z, and A-axes, the five-axis machine can tilt or rotate the workpiece or cutting tool along the B-axis. This additional axis allows for more complex and simultaneous movements, enabling the tool to approach the workpiece from multiple angles. Five-axis machines provide greater flexibility and maneuverability, making it possible to machine complex geometries and perform machining operations in a single setup.

The key advantages of five-axis machining over four-axis machining include:

a) Enhanced Precision: Five-axis machining enables the tool to maintain a more optimal cutting angle, resulting in improved surface finish and precision. It reduces the need for multiple setups, which can introduce cumulative errors.

b) Reduced Setup Time: Five-axis machines can perform complex machining operations in a single setup, eliminating the need for repositioning the part. This leads to reduced setup time and increased overall efficiency.

c) Greater Design Freedom: The additional B-axis in five-axis machining allows for more freedom in part design. It enables machining of undercuts, deep cavities, and intricate features that may be challenging or impossible to access with a four-axis machine.

d) Shorter Production Time: With the ability to approach the part from multiple angles, five-axis machining can significantly reduce cycle times. It minimizes tool changes and maximizes cutting efficiency, resulting in faster production times.

e) Improved Tool Life: Five-axis machining distributes the cutting forces more evenly, reducing tool wear and extending tool life. This benefit is particularly advantageous when machining harder or more abrasive materials.

While both four-axis and five-axis machining have their respective advantages, the choice depends on the specific requirements of the part, the complexity of the geometry, and the desired production efficiency. Five-axis machining is generally preferred for highly complex parts that require precise and efficient machining from multiple angles. However, four-axis machining can still be a cost-effective and practical solution for many applications.