Message

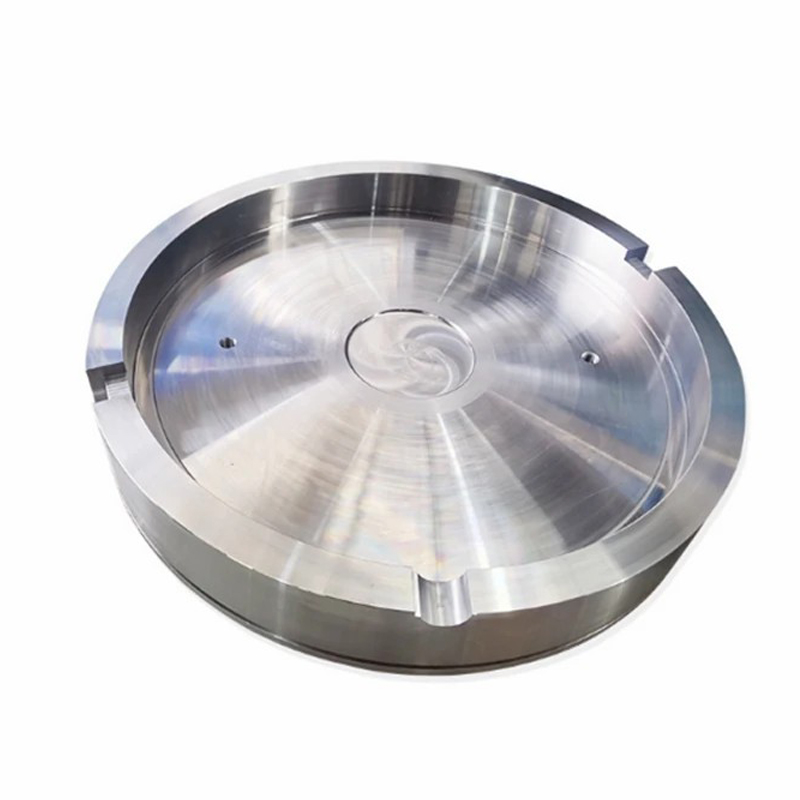

CNC five axis machining is an advanced CNC machining technology used for machining complex shaped workpieces in three-dimensional space. Traditional CNC machining typically involves machining on three rotational axes (X, Y, Z), while five axis machining adds two rotational axes (A, B) to this foundation, allowing the workpiece to be cut in a more free angle and direction.

The main feature of five axis machining is the ability to achieve optimal matching between multiple cutting tool trajectories and workpiece surfaces, thereby completing more machining operations in one clamping, reducing workpiece re clamping and alignment errors, and improving machining accuracy and efficiency. Through five axis machining, complex shaped workpieces can be completed in a relatively short time, reducing the need for multiple clamping and repositioning processes in traditional machining.

Five axis machining is widely used in aerospace, automotive manufacturing, mold manufacturing, medical equipment, shipbuilding and other fields, especially for workpieces with complex surfaces, porous machining, thin-walled structures and other high requirements. Five axis machining can provide better machining quality and accuracy.

It should be pointed out that five axis machining requires high requirements for machining equipment and programming technology, involving technical aspects such as machine tool structure, motion control system, and tool path planning. At the same time, operators need to possess relevant skills and experience to ensure safe and efficient processing.