Message

1、 Preliminary preparation

Material preparation:

According to the design requirements of automotive shock absorbers, choose high-strength steel or aluminum alloy with good ductility and plasticity as the raw material.

According to the design drawings, cut the material into the required size and shape.

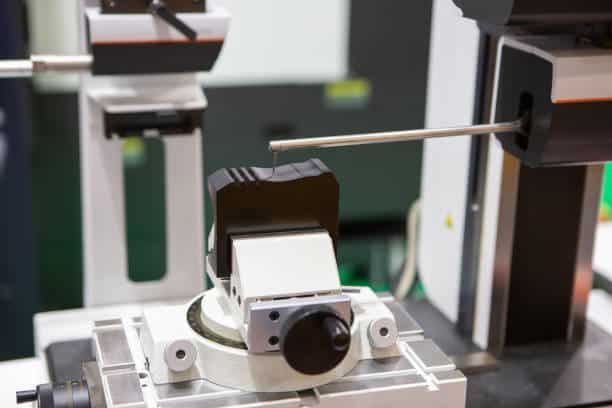

Fixture design:

Design and manufacture appropriate fixtures to ensure the stability and accuracy of shock absorber components during the machining process.

2、 CNC machining

Rough machining:

Rough machining of shock absorber components using CNC milling machines to preliminarily form the required shape and size.

Precision machining:

Precision machining of shock absorber components using CNC 4-axis (or 5-axis) milling machines or CNC lathes to ensure accurate dimensions and smooth surfaces of the components.

As needed, it may also include polishing treatment to further improve the surface smoothness and flatness of the components.

Welding joint treatment:

If the shock absorber components involve welding, the surface of the welded joint must be polished to ensure welding quality.

3、 Post processing spray:

Spray paint the outer shell of the shock absorber to protect the surface of the product from external oxidation, corrosion, wear, and other influences.

Control the formula and spraying amount of the coating to ensure uniform color and no defects such as dripping, peeling, and foaming.

Conduct quality inspection on the processed shock absorber components, including dimension measurement, surface quality inspection, etc.Ensure that all components meet design requirements and quality standards.

4、 Assembly and testing assemble:

Assemble the processed shock absorber components to form a complete shock absorber product.

Performance testing:

Conduct performance tests on the assembled shock absorbers, including testing of shock absorption effectiveness, durability, and other indicators.

Ensure that shock absorber products meet the requirements and safety standards for automotive use.

During the entire CNC machining process of automotive shock absorbers, it is necessary to strictly control machining parameters, select appropriate machining equipment and fixtures, and ensure machining accuracy and product quality. At the same time, attention should also be paid to issues such as material selection and optimization of processing technology to improve the performance and reliability of shock absorbers.