Message

In the automotive industry, the brake absorber (Shock Absorber) is a vital component, which is responsible for reducing the braking performance, driving comfort and safety caused by uneven road surfaces when the vehicle is driving. With the development of the automobile industry, the requirements for the performance and precision of fabric absorbers are getting higher and higher. Therefore, it has become a trend to use advanced processing technology such as CNC (computer numerical control) machine tool processing technology to manufacture fabric absorbers.

Introduction to CNC Machine Tool Processing Technology

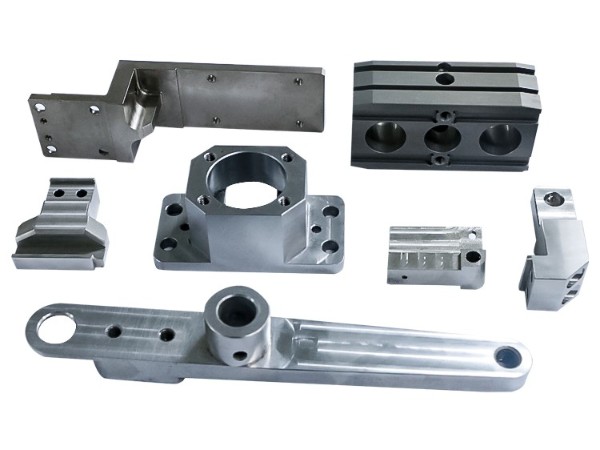

CNC machine tool machining technology is a process that controls machine tools through computers. It utilizes digital technology to precisely control various parameters during the machining process, such as cutting speed, feed rate, cutting depth, etc., through computers, thus achieving precise machining of parts. CNC machine tool processing technology has advantages such as high precision, high efficiency, and high degree of automation, and is widely used in manufacturing fields such as automobiles, aviation, and molds.

The Application of CNC Machine Tool in the Manufacturing of Vibration Absorbers

High precision machining: CNC machine tools can achieve high-precision machining of vibration absorber parts, ensuring that the dimensional and shape accuracy of the parts meet design requirements. This is crucial for ensuring the performance of vibration absorbers.

Complex shape machining: The parts of vibration absorbers often have complex shapes and structures, and traditional machining methods are difficult to meet the requirements. CNC machine tools can process complex shaped parts through

programming, greatly improving production efficiency.

High degree of automation: In the CNC machining process, workers only need to set the program, and the machine can automatically complete the machining tasks, reducing the labor intensity of workers and improving production efficiency.

The advantages of CNC machine tool processing technology

High production efficiency: CNC machine tools can work continuously with high machining accuracy, reducing scrap and repair rates during the machining process and improving production efficiency.

Stable quality: CNC machine tools control the machining process through computers, ensuring consistency and stability in machining, and improving product quality.

Flexible design: CNC machine tools can be programmed according to different design requirements, with high flexibility to meet the personalized needs of different customers.